Vulcan Elements, a 2-year-old startup manufacturing rare earth magnets in North Carolina, has quietly landed more than $10 million in Defense Department contracts across every branch of the U.S. military.

The deals underscore how urgent the Pentagon’s need has become to build a domestic supply chain for one of the most critical components in modern technology. China currently produces 94% of the global supply and cut off magnet exports in April.

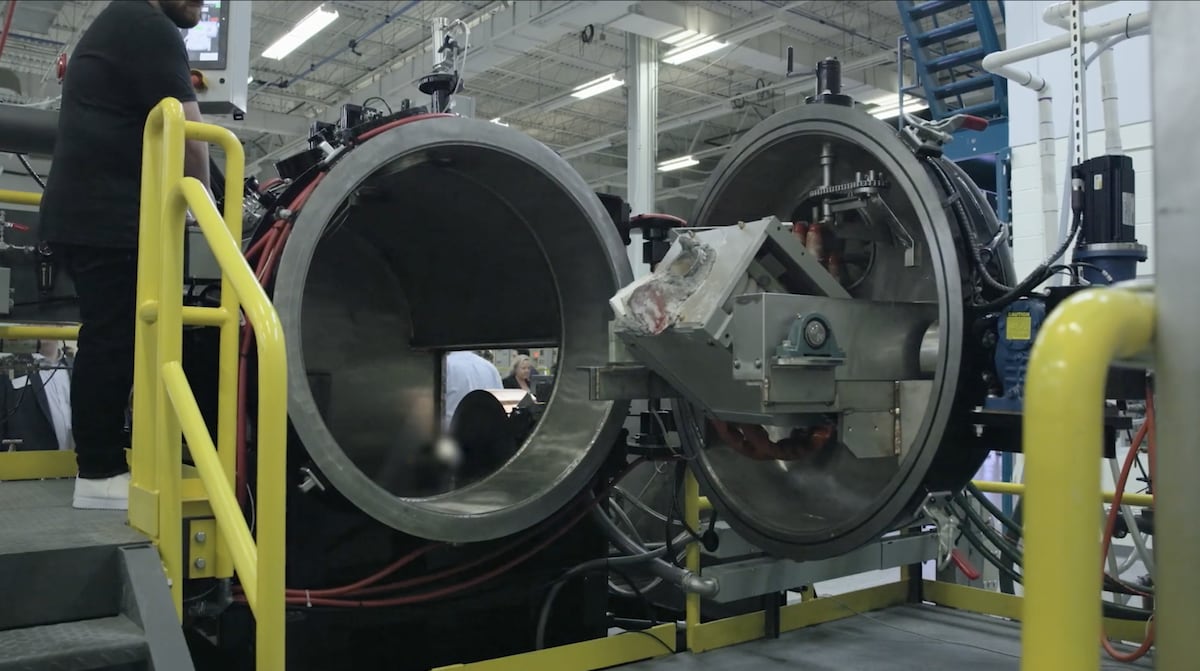

The company, founded by former U.S. Navy officer John Maslin, said it has secured nine DOD contracts in the past eight months. Vulcan opened its manufacturing facility doors on March 31 and is delivering on initial contracts over the next 60 days, Maslin told Defense News.

Vulcan is supplying magnets for ground vehicles, shipbuilding, munitions, drones, satellites and other priority defense programs, directly through the DOD and in partnership with defense primes and subcontractors.

These magnets are the “invisible building blocks of our economy” and are found in every advanced military system from motors to sensors to actuators and generators, Maslin said. “If you don’t have them, you can’t build the end item,” he added.

The DOD contracts arrive as Vulcan announced a $65 million Series A funding round earlier this month, led by Altimeter Capital with participation from One Investment Management.

“This Series A enables Vulcan to scale with the speed and seriousness that this moment and the nation demand,” Maslin said in the company’s announcement. “If we execute with discipline, we can rebuild one of the most critical supply chains of the 21st century — on U.S. soil.”

The capital will allow the company to move beyond its current 10-metric-tonnes-producing pilot facility in Durham, where it has already demonstrated production of several magnet grades validated by the Department of Energy, toward full commercial scale, according to Maslin.

Vulcan expects to bring several hundred tonnes of annual capacity online within a few years and thousands of tonnes by the end of the decade. A tonne equates to 1,000 kilograms or approximately 2,204 pounds.

The new money enables Vulcan to expand the number and scale of contracts it can execute, pushing forward on qualification programs with multiple branches of the armed services and major defense contractors, Maslin said.

“From day zero this company was built to make magnets for defense, aerospace and critical economic industries in that order,” he said.

The Pentagon has elevated magnets to the same level of strategic urgency as semiconductors and batteries. Congress, in the fiscal 2023 National Defense Authorization Act, directed the Defense Department to brief lawmakers on a magnet manufacturing strategy, and new rules now require proof of provenance for magnets in U.S. defense systems, effectively banning Chinese inputs.

Vulcan’s pitch is that it is fully “decoupled” from China at every level from ownership, equipment, software, and raw materials and can meet those traceability requirements. Its process, validated by the Department of Energy’s Ames Laboratory, uses U.S. and allied inputs exclusively.

The urgency isn’t limited to defense. Rare earth magnets are essential for artificial intelligence data centers, robotics, electric vehicles and semiconductor manufacturing equipment. Demand is expected to climb exponentially, Maslin said.

For now, Vulcan’s 10-tonne output is “a drop in the bucket,” Maslin admits, but the startup argues that mastering magnet production at any volume is an achievement in itself.

The process isn’t as simple as pushing a button, Maslin noted.

“It’s complex, advanced manufacturing, you’re dealing with metallography, crystal structures, powdered metals. It is phenomenally difficult to get this right, and whether it’s one tonne or 1,000 tonnes, if you can’t make a magnet, it doesn’t matter.”

With the new funding, Vulcan is hiring engineers and technicians to staff its next facilities as it ramps toward industrial scale. The company is betting that what’s now a series of small contracts with every military branch will grow into a cornerstone role in the nation’s bid to onshore one of the last critical choke points in the global supply chain.

Jen Judson is an award-winning journalist covering land warfare for Defense News. She has also worked for Politico and Inside Defense. She holds a Master of Science degree in journalism from Boston University and a Bachelor of Arts degree from Kenyon College.

-3.png)